The ocean is a huge treasure, containing infinite treasures. It is urgent to master key technologies for deep-sea infiltration, exploration, and development, safeguard marine rights, and develop marine resources.

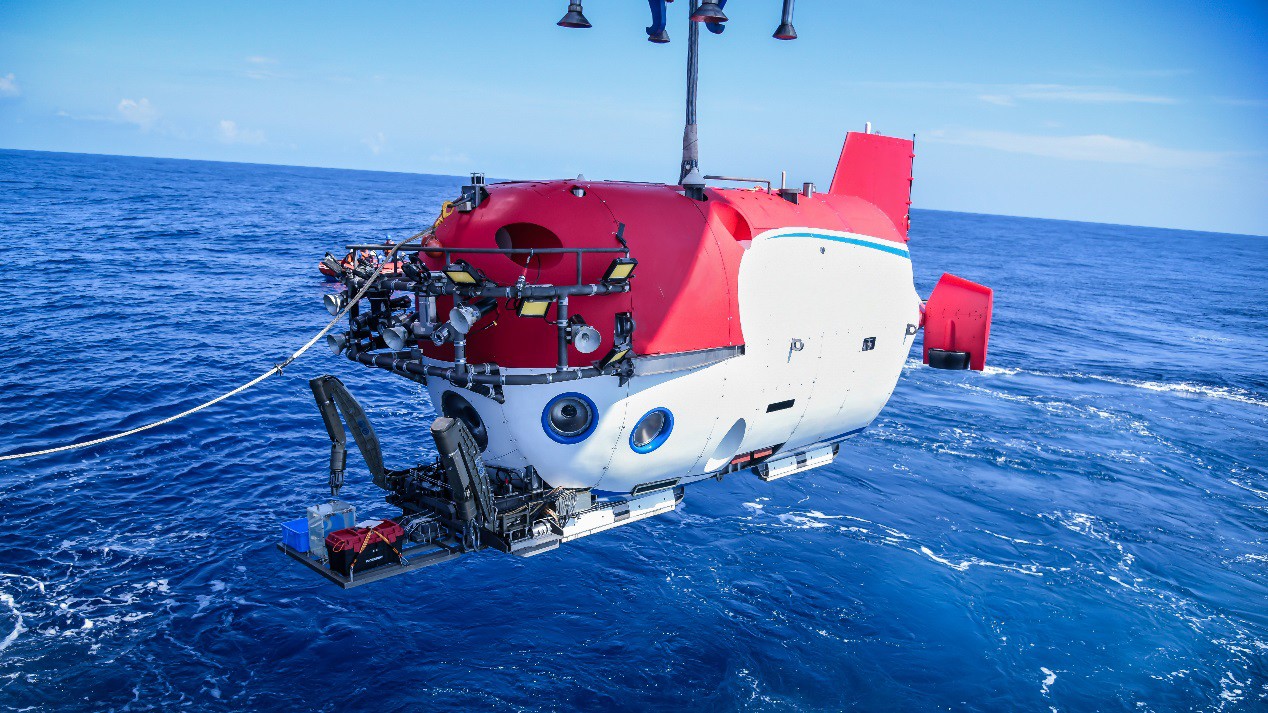

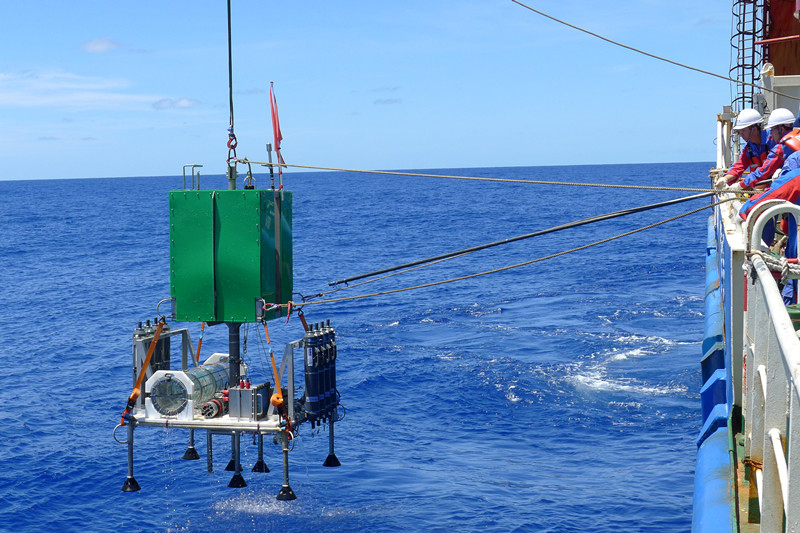

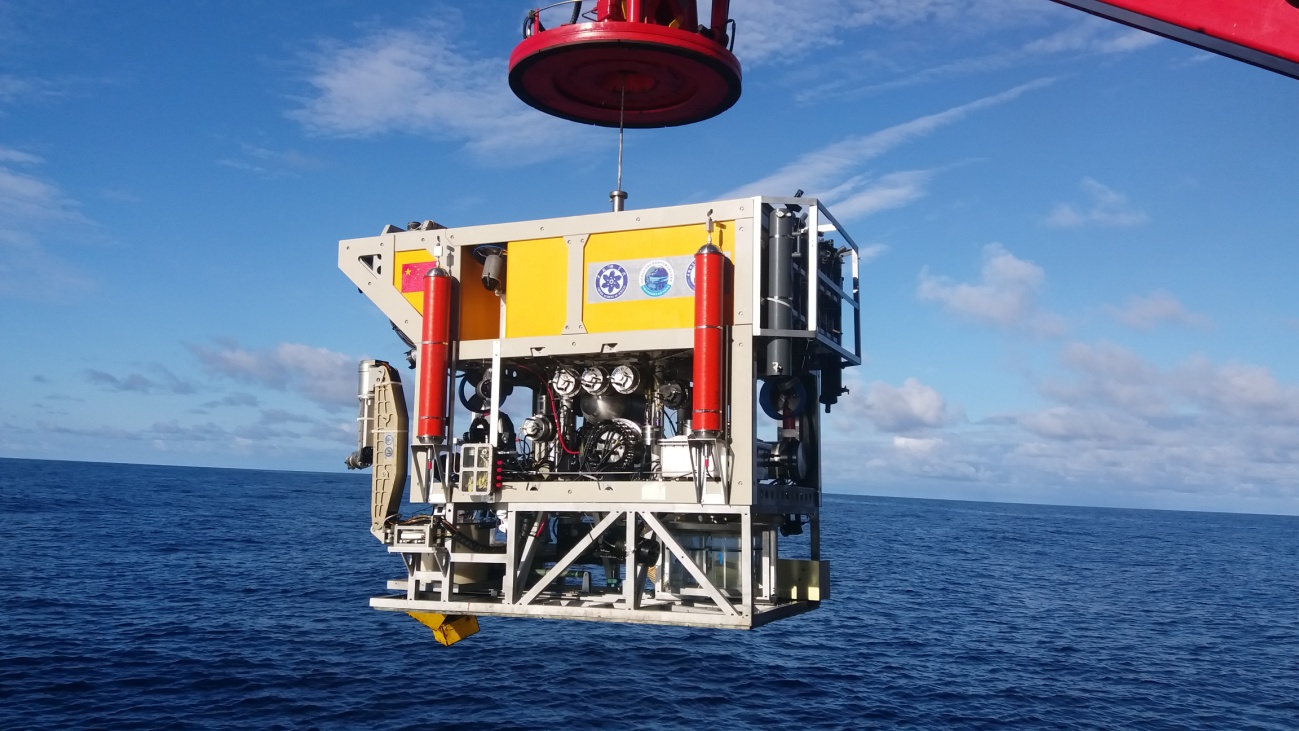

The development of deep-sea intelligent equipment for manned vehicles is the key to implementing China's deep-sea strategy, and deep-sea power is the power supply guarantee for deep-sea equipment. Deep sea power sources need to meet the stringent requirements of high voltage resistance, high safety, and high energy density.

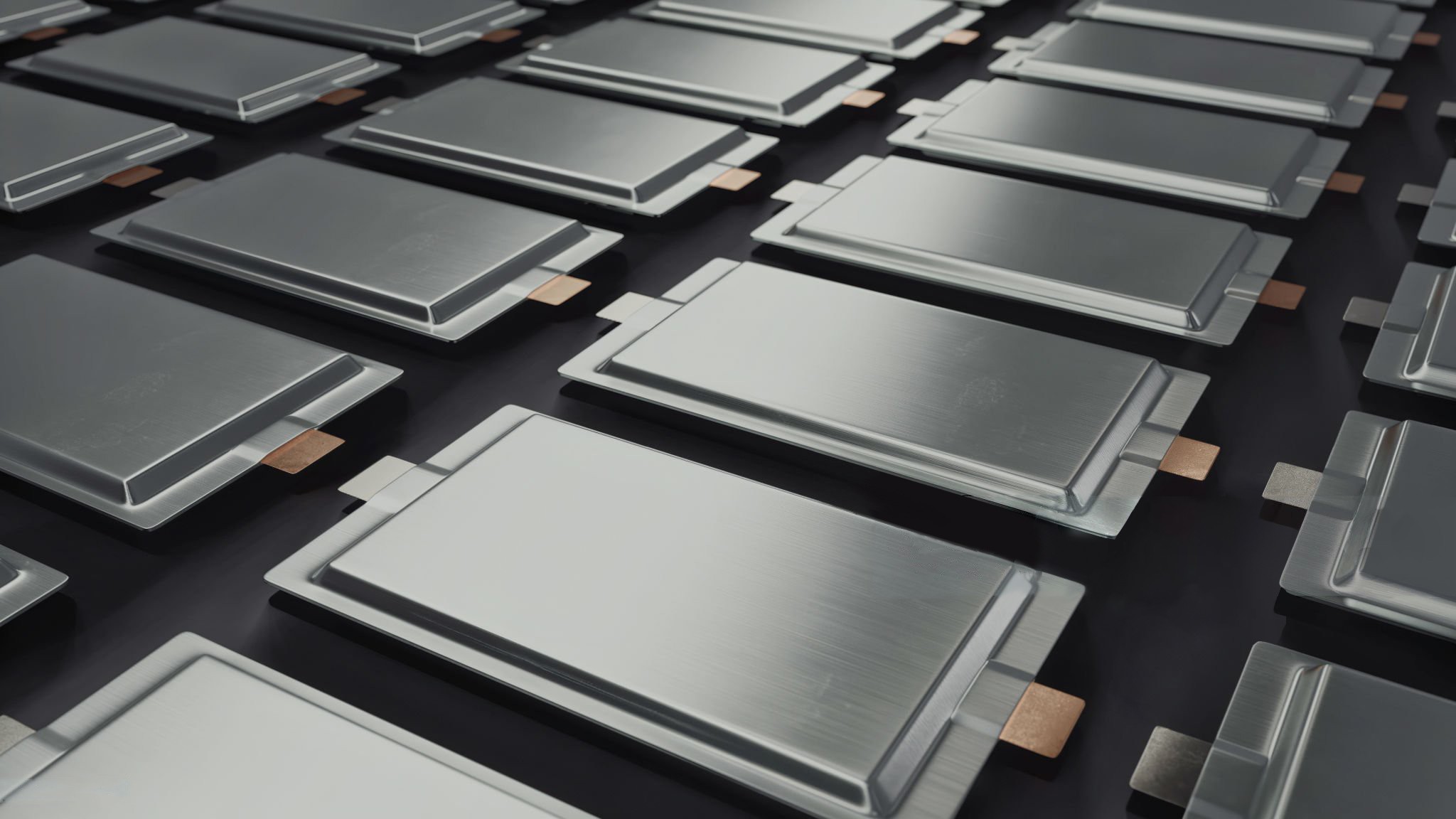

What kind of battery can meet the requirements of deep-sea power supply? Among the current commercialized power supply systems, lithium-ion batteries are the most widely used and mature, with the highest energy density. The use of lithium-ion batteries can improve the endurance time of deep-sea equipment, save space, and meet the needs of deep-sea equipment load and intelligence.

Commercial lithium-ion batteries mainly consist of a positive electrode, negative electrode, liquid electrolyte, and separator. When supplying energy to deep-sea equipment, both lithium ions and electrons depart from the negative electrode, the ions pass through the electrolyte, and the electrons reach the positive electrode through an external circuit to complete the power supply. Electrolytes are an important part that determines the safety and stability of batteries. However, existing systems generally use liquid organic electrolytes to conduct lithium ions, which have low flash points, are flammable and explosive, and are not resistant to deep-sea high pressure, posing significant safety hazards.

Replacing liquid electrolytes with solid electrolytes can significantly improve the safety performance of lithium batteries. However, how to balance mechanical strength and ion transport is a bottleneck problem that solid-state electrolytes need to solve.

Some solid electrolytes have a too high Young's modulus to withstand deep-sea high pressure, just like hard and brittle glass, which is prone to fracture under stress. Such materials are prone to cracking under deep-sea high pressure, causing material breakage and affecting ion transport. However, some solid electrolytes have a too small Young's modulus, which is simply too soft and prone to deformation like dough. Although these electrolytes usually have better ion transport performance, they cannot provide sufficient mechanical strength to support the battery against ultra-high water pressure in the deep sea, resulting in huge volume deformation that often leads to battery failure or even safety accidents such as explosions.

In order to solve this bottleneck problem, Zhongke Shenlan Huize proposed a design concept of combining rigidity and flexibility. This project uses strong and tough materials as the "rigid" skeleton to ensure that the electrolyte is hard enough. By using composite flexible ion transport materials to achieve both strength and toughness of the electrolyte, an efficient ion transport pathway is created using the interface of rigidity and flexibility, and a polymer based composite solid electrolyte with excellent comprehensive performance is developed.

In solid-state batteries, the contact between electrode materials and electrolytes is a point-to-point contact between the solid and solid interface. After multiple charge and discharge cycles, the electrode undergoes volume deformation, and cracks occur between the solid electrode and electrolyte due to stress, resulting in contact failure between the electrode and electrolyte, leading to a decrease in battery capacity.

In order to solve this problem, our company has initiated in-situ thermal polymerization of electrolytes through high-temperature synthesis process, developed in-situ curing interface fusion technology to achieve seamless contact between solid electrolytes and solid electrodes, achieve efficient ion transport, and significantly improve the cycling life of batteries.

Based on the above two key technologies, the safety and stability of battery cells have been significantly improved, ensuring that they can better serve deep-sea equipment. In addition, the solid electrolyte that combines rigidity and flexibility also has a wider electrochemical window and higher ion conductivity, which means that the battery has higher energy density, better long-term endurance, and stronger power performance.

Compared with liquid batteries, Zhongke Shenlan Huize solid-state battery cells can undergo multiple nail piercing experiments.

The solid-state battery has also passed third-party testing of the 8000 meter and 11000 meter pressure chambers at the National Deep Sea Base Management Center, demonstrating good resistance to deep-sea high pressure.

Up to now, we have provided 68 batches of power systems for various deep-sea diving equipment, serving deep-sea equipment such as Wanquan, Tianya, Haijiao, Fenghuang, Jinji, Haidou, Luling, and Canghai, achieving "zero" accident safe operation and receiving high praise from users.